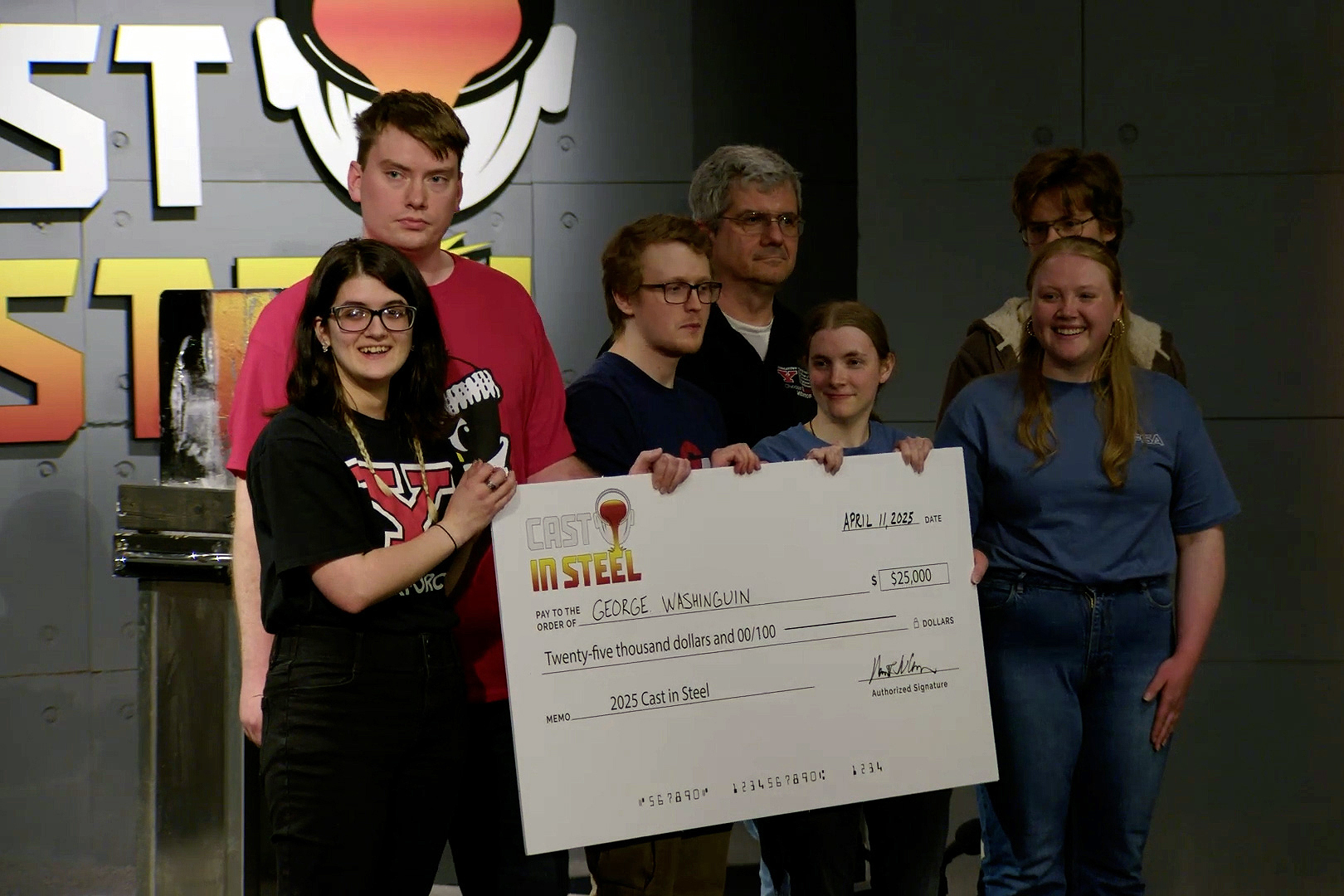

YSU American Foundry Society wins top honors at national casting competition in Atlanta

The Youngstown State University chapter of the American Foundry Society took home top honors at the 2025 Steel Founders’ Society of America’s Cast in Steel Competition in Atlanta, Georgia.

The five-member YSU team won Best in Show, placing first overall out of 36 collegiate teams nationwide. The team also received first place for Best Performance, second place for Best Casting and second place for Best Design and Process.

The Cast in Steel 2025 competition challenged university students to use modern casting tools to creatively design and produce a functioning version of a sword for George Washington. Teams were to produce a replica of one of Washington’s actual swords or to design one based on his known preferences and needs. Entries were judged by professionals from the steel casting industry, as well as celebrity judges Ben Abbott and Dave Baker from the History Channel series “Forged in Fire.”

Coleman Buchanan, graduate student in the mechanical engineering program and AFS treasurer, led the blade team with insight on material selection and heat treatment while Joseph Barlett, mechanical engineering technology major and AFS secretary, led the research in selecting materials suitable for the blade.

“A lot of teams used knife steels, which are made to stay sharp but not take impact,” Bartlett said. “A sword isn’t just a big knife, it’s closer to a sharp club. You want it to flex and take hits without shattering.”

Elly Volz, business administration major with mechanical engineering technology experience and AFS president, led the hilt team which includes the handle and balance for the sword. Their sword is modeled as a classic saber-style full handguard that accommodated the casting process and matched the style of the historical period. Ely Vuksanovich, mechanical engineering technology major and AFS vice president, created the sword’s stars and stripes motif and the ‘E Pluribus Unum’ motto.

Team member Victoria Mathews, a first-year mechanical engineering student, said the experience expanded her view of the industry. “I originally joined because I love swords but now I’ve learned so much about casting,” Mathews said. “There’s way more to it than I expected.”

Brian Vuksanovich, professor and faculty advisor said, “Judges praised the YSU design for its exceptional balance, usability and structural integrity which in turn ended up being a key advantage.”

The group started work on the project in August and a major decision was to split the team to work on the blade and hilt simultaneously. “The team reviewed the past two years’ performances, learned from those mistakes, and made corrections,” said faculty advisor, Vuksanovich. “The blade design was essentially finished by early December, and we poured the molds by the end of February. Since the design produced an almost complete sword, all that remained was polishing and wrapping the handle. We finished three weeks ahead of the deadline.”

Buchanan led the technical report effort which resulted in the team’s placing for Design and Process documentation. The video for the team’s work was completed by Ely Vuksanovich and is featured on the SFSA YouTube channel.

“It’s a small club, just the five of us this year,” Vuksanovich said. “But we handled everything ourselves, and I’m really proud of that. We’re definitely looking for new members for next year.”

The project was completed with support from several regional industry partners. The 3D-printed sand molds were created by Humtown Products, through Mark and Brandon Lamoncha. Steel casting was completed at Trumbull Metals under the supervision of Corey Jarvis. Heat treating was done at Youngstown Heat Treat by John Kish, and the bronze casting for the hilt was performed at Oakes Foundry in Warren by Kylie Acierno.

Finishing work was done in Bliss Hall at YSU with help from Chauncey Hay of the University’s art department. Financial support came from the YSU Student Government Association and Wim Steelant, dean of YSU’s college of STEM, which made it possible for the team to attend the national competition. The chapter also received casting simulation support from MAGMASOFT, which provided software licenses now being used in the engineering curriculum at YSU.

“This kind of experience is priceless,” Bartlett said. “We got to use real materials, real processes and bring home real awards.”

The YSU American Foundry Society chapter is currently recruiting new members and welcomes students from all majors who are interested in metallurgy, design or manufacturing engineering. For more information, please contact Brian Vuksanovich at bdvuksanovich@ysu.edu.